|

ITEM

|

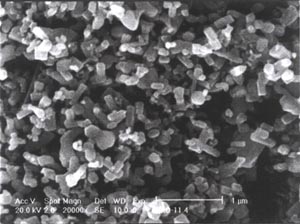

Zinc Oxide

|

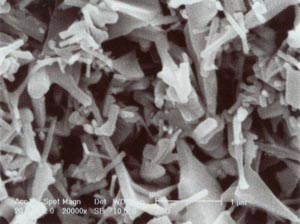

Tetrapod zinc oxide

|

|

ZnO %≥

|

99.90

|

99.90

|

|

Pb %≤

|

0.005

|

0.005

|

|

Cd %≤

|

0.003

|

0.003

|

|

Fe %≤

|

0.003

|

0.003

|

|

Cu %≤

|

0.003

|

0.003

|

|

Sn %≤

|

0.001

|

0.001

|

|

Al %≤

|

0.001

|

0.001

|

|

As %≤

|

0.001

|

0.001

|

|

Sb %≤

|

0.001

|

0.001

|

|

Average size nm≤

|

30

|

200

|

|

Bulk dengsity g/cm3≤

|

0.4

|

0.2

|

|

L.O.I. sqm/g

|

4.8-6.8

|

|

Zinc Oxide (D50: 1um )

|

|

T-ZnOw

Nano T-ZnOw

Nano-tetrapod zinc oxide whiskers are prepared by vapor-phase oxidation of zinc pig under high temperature. The effects of content of molecular sieve, reaction temperature and system pressure on the morphology of T-ZnO, are examined. The products are identified to be pure ZnO with wurtzite structure by X-ray diffraction analysis (XRD). But EDS analysis shows that the atom ratio of oxygen and zinc is below 1. The scanning electron microscopy (SEM) investigation indicates that content of molecular sieve, reaction temperature and system pressure have great effects on the morphology of T-ZnOw. Under constant pressure, the morphology of the whiskers changes with the increasing of reaction temperature. Nano T-ZnO, with complete and uniform structure can be obtained when the pressure and temperature are 11083Pa and 1038℃ respectively. While underconstant temperature, the dimension of the products reduces with the reducing of the pressure. Uniform nano T-ZnO. with root dimension of 20nm to 80nm and length of 300nm to 2μm could be obtained when the pressure is lower than 11083Pa.

|

四针状氧化锌晶须

氧化锌晶须(ZnOw),白色疏松状粉体,立体四针状显微结构,很容易实现在基体材料中的三维均匀分布,从而各向同性地改善材料的物理性能, 同时赋予材料多种独特的功能特性。 氧化锌晶须主要物理特性: 独特的立体四针状显微结构,每根针状体为单晶体或纳米晶微纤维 针状体及尖端纳米效应 抗菌、防藻、催化特性 半导体、压电、压敏特性 超高强度:单晶体纤维的强度达到或接近化学键的理论计算值 耐高温:在1720℃之前不以生变化 氧化锌晶须用途 作为结构及功能材料,可广泛应用于国防、电子、化工、轻工、交通等领域,赋于材料及制品优异的抗菌、抗静电、耐磨、减振、防滑、降噪、吸波、抗老化、抗冲击等性能。 以金属锌为原料,真空条件下制备纳米四针状氧化锌晶须(T-ZnOw),反应条件对氧化锌结晶形貌的影响。表面能谱证实产物只含锌和氧原子,但氧原子数少于化学计量,表明T-ZnOw在缺氧环境中生长。XRD物相分析表明:产物为纯的六方晶系纤锌矿结构;SEM研究表明:分子筛用量、反应温度、体系压力对产物的形态影响很大。

|